As an important part of steel products, steel pipes are divided into seamless steel pipes, welded steel pipes and cast steel pipes according to their manufacturing processes. Seamless steel pipes are made by hot rolling. Weld steel pipes are made of welding hot-rolled coils or strip blanks. Cast steel pipes are obtained by casting. To improve the strength and toughness of steel pipes, heat treatment is generally required. For high-impact steel pipes, the heat treatment is quenching plus high-temperature tempering. Quenching heat treatment causes great deformation and even defects.

The heat treatment of high-impact bainite steel is obtained by normalizing, and the heat treatment deformation is less, which can avoid quenching defects and obtain better strength, toughness and wear resistance. Various types of bainitic steels have been used in mining, electric power, petroleum and construction machinery. For steel pipe materials, adopting an appropriate normalizing temperature can refine the structure of the steel pipe and improve its mechanical properties. For steel pipes with low strength, there are currently relevant studies on the influence of normalizing temperature on its structure and properties, such as the study of the effect of normalizing temperature on the microstructure and properties of steel pipes with a strength of 491 to 499Mpa. The results show that the mechanical properties are the highest when normalizing at 830°C.

The effect of normalizing temperature on the microstructure and properties of high-frequency resistance welded steel pipes with a strength of 460Mpa. The results showed that when the steel pipe was heated in the range of 850 to 1000°C. The strength of the steel pipe was high when the temperature exceeded 950°C. The welding seam zone is within the normalizing heating temperature range of 900 to 1000°C; the strength increases with the increase in the heating temperature. However, for high-impact steel pipes, there are few literatures on the influence of normalizing temperature on its microstructure and mechanical properties. Therefore, by studying the influence of normalizing temperature on the microstructure and mechanical properties of the newly developed high-impact carbide-free bainite steel pipes, the appropriate normalizing heating temperature is determined, which is the normalizing austenitization temperature of the actual bainite steel pipe. The determination provides a reference and has important practical significance for the formulation of the actual heat treatment process parameters of carbide-free bainitic steel pipes.

1. Experimental materials and methods

The experimental subject is a newly developed bainite steel pipe. The steel pipe is made by the manufacturer. The chemical composition of the tested bainite steel pipe is that w(c) is 0.08% to 0.15%, w(Si) 0.8 % to 1.5% and w(mn) plus w(cr) plus w(mo) plus w(V) less than and equal to 3%. The production processes of bainite steel pipes are smelting by electric furnaces, ladle refining vacuum, continuous casting into ingots with a diameter of 430mm. The steel ingot is heated, hot pierced, continuous rolling, sizing and cooling bed cooling, and hot rolled into a steel pipe with a size of 420mm×16mm. The sample is taken from the hot-rolled steel pipe. The JB-300 pendulum impact testing machine is used to impact the sample, and it is processed into a V-shaped notch impact sample of 10mm×10mm×55mm; the sample is stretched by the ddl300 tensile testing machine. It is processed into a standard short tensile sample with a diameter of 8 mm. Use a niKon EpiHot-300 microscope to observe the metallographic structure of the sample, and the tissue corrosion solution is 4% of nitric acid alcohol solution; use a Quanta 400 scanning electron microscope to observe the morphology of the sample; use the X-ray diffractometer to analyze the phase of the experimental subject. According to the measurement results of the ac3 phase transition temperature of the experimental subject, the normalizing heat treatment heating temperatures of the experimental materials were determined to be 850°C, 870°C, 890°C, 910°C, 930°C, 950°C and 970°C, and the holding time was 30 minutes. Since the strength and toughness of bainitic steel pipes are high when tempered at 250 to 350°C, different temperatures are selected for normalizing and then tempered at 300°C. The heat treatment equipment is cY00-1 box-type resistance furnace.

2. Experimental results and analysis

2.1 The effect of normalizing temperatures on mechanical properties of bainite steel pipes

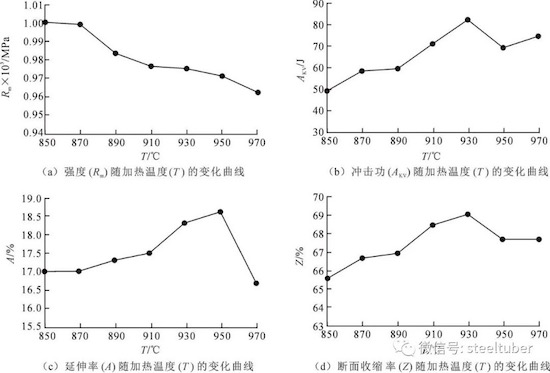

Figure 1 is the influence curve of normalizing temperature (t) on the mechanical properties of high-impact bainite steel pipes. It can be seen from Figure 1(a) that the strength (rm) of bainitic steel pipes tends to decrease with the increase in the normalizing temperature, but the change is not great. The tensile strength is between 1000 and 962Mpa. Therefore, Bainitic steel pipes have high strength at low temperatures heating at different temperatures. Figure 1(B) is the change curve of impact energy (Akv) of carbide-free bainite steel pipe with normalizing temperature. It can be seen from Figure 1(B) that the impact energy tends to increase with the increase in normalizing temperature. When the heating temperature is 930°C, the maximum impact energy appears, which is 82.6J. When the heating temperature exceeds 930°C, the impact energy decreases. Figure 1(c) is the change curve of elongation (a) of bainite steel pipes with normalizing temperature. It can be seen from Figure 1(c) that with the increase in normalizing heating temperature, the elongation tends to increase. There is a peak value at 950°C; when the heating temperature is 930 to 950°C, the elongation index is relatively high, from 18.3% to 18.6%; when heated above 950°C, the elongation rate decreases; when heated at 970°C, the lowest elongation index is 16.5%. Figure 1(d) is the variation curve of the reduction of area (z) of bainite steel pipes with heating temperature. It can be seen from Figure 1(d) that the reduction of area tends to increase with the increase in normalizing heating temperature. When heated at 930℃, the peak value appeared for the reduction of area, and when heated above 930°C, the reduction of area decreases.

The reason why the mechanical properties of bainite steel pipes change with the normalizing temperature is that with the increase in the normalizing heating temperature, the austenite transformation is relatively complete, and the solid solubility of alloy elements in the austenite structure increases, which improves the hardness of austenite, increases the amount of retained austenite in the structure after normalizing heat treatment, increases the toughness, and reduces the strength. However, when the temperature is too high, the structure of the bainitic steel pipe grows, resulting in coarsening of the grains, reducing the strength and plasticity. When heated above 950°C, the impact energy increases. Although the structure is coarse, the excessive heating temperature will increase the amount of retained austenite in the structure and improve the toughness. Although the tensile strength value of the experimental subject is not the highest when heated at 930°C, compared with other heating temperatures, the decrease in tensile strength is not great. The elongation and area reduction are great. The impact energy is the highest at 930°C. Therefore, from the perspective of the combination of strength and toughness, the best normalizing temperature for bainite steel pipes is 930°C. The mechanical properties obtained by heating and air cooling at 930°C and tempering at 300°C are that rm is 71Mpa, a 18.3%, z 69%, and Akv 82.6J.

(a) Variation curve of strength (Rm) changed with heating temperatures (T)

(b) Variation curve of impact energy (Akv) changed with heating temperatures (T)

(c) Variation curve of elongation (A) changed with heating temperatures (T)

(d) Variation curve of reduction of area (Z) changed with heating temperatures (T)

Figure 1 Variation curve of mechanical properties of carbide-free bainite steel pipes changed with normalizing temperatures