The material and quality of steel pipes directly determine their pressure-bearing capacity. Common pipeline materials include carbon steel, stainless steel, and alloy steel. Different materials possess varying strengths and pressure resistance. For instance, carbon steel has a superior pressure-bearing capacity at room temperatures, while stainless steel offers better corrosion resistance and high-temperature performance. The wall thickness of the pipeline directly affects its pressure-bearing capacity. Generally, for pipelines of the same material and diameter, the thicker the wall, the greater its pressure-bearing capacity. In engineering design, the appropriate pipe wall thickness is typically selected based on the pressure requirements and the purpose of the pipeline.

The pipe diameter is also a crucial factor influencing the pressure-bearing capacity. Pipes with larger diameters can withstand greater forces at the same pressure. Therefore, in high flow requirements or high-pressure working environments, selecting pipes with larger diameters can enhance the pressure-bearing capacity of the system.

Common pipe connections include welding, threading, and flanges. Different connection methods significantly impact the pressure-bearing capacity of the pipe. For instance, welding connections can provide a continuous metal structure with high sealing and strength, suitable for high-pressure and large-diameter pipe systems. The internal pressure of the pipe is a direct factor in assessing its pressure-bearing capacity. The working pressure inside the pipeline system must be accurately calculated and predicted in engineering design to ensure that the pipeline operates safely within its design life.

Additionally, the processing technology and heat treatment method of the steel pipe also influence its pressure-bearing capacity. For instance, steel pipes produced by cold drawing or hot rolling processes can significantly improve their compressive strength and corrosion resistance if properly heat-treated. Therefore, when selecting steel pipes, besides considering the material, wall thickness, and diameter, it is also necessary to consider the manufacturing process and whether the necessary heat treatment has been performed. The design and standards of the steel pipe are also crucial. Following industry standards such as ASTM or DIN ensures that the steel pipe can withstand the expected working pressure. Regular inspection and maintenance should not be neglected. By evaluating the internal condition of the steel pipe through ultrasonic testing or X-ray testing, potential defects can be discovered in time to prevent safety accidents caused by insufficient pressure. In practical applications, the installation method and working environment of the steel pipe also influence its pressure-bearing capacity. Correct installation and a suitable working environment can ensure that the steel pipe is not influenced by external factors such as temperature changes and chemical corrosion, thereby maintaining its excellent pressure-bearing performance. Therefore, a comprehensive consideration of material selection, design standards, processing technology, and installation and use conditions is crucial to ensuring the pressure-bearing capacity and extending the service life of the steel pipe, especially in high-risk industrial applications. The welding quality of the steel pipe is also a key factor influencing its pressure-bearing capacity. High-quality welding technology can ensure the strength and sealing of the weld area, preventing leakage or breakage under high-pressure environments. Therefore, choosing an experienced welding team and using suitable welding materials are crucial to improving the overall performance of the steel pipe. Additionally, for specific applications, the coating treatment of the inner wall of the steel pipe can enhance its corrosion resistance and wear resistance, further improving its performance under extreme conditions. In short, every production link and maintenance measure of the steel pipe directly affect its final pressure-bearing capacity and service life.

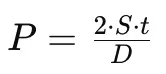

Calculation method

Here, P is the pressure-bearing capacity of the pipeline; S is the allowable stress of the pipeline material; t is the wall thickness of the pipeline; and D is the outer diameter of the pipeline. This formula provides a method for estimating the maximum allowable internal pressure of the pipeline under specific conditions. The engineering designer will perform detailed calculations and analyses based on specific engineering requirements and the actual situation of the pipeline, combined with the above-mentioned influencing factors, to ensure that the pipeline system operates safely and reliably within its design life.