3. Requirements for Post-Weld Heat Treatment

The combination of steel hardenability, diffusible hydrogen content in the deposited metal, and the stress state of the weld joint can lead to cold cracks. Post-weld heat treatment is essentially a localized high-temperature tempering of the weld joint, aimed at relaxing residual stress, reducing diffusible hydrogen, and improving structural properties. Cold cracks may occur in the weld joint when the carbon content approaches the material's upper limit or when welding rigid components at low temperatures. In such cases, heat treatment can eliminate residual stress and prevent delayed cracking.

3.2 Main Parameters

The key parameters of post-weld heat treatment include heat treatment temperature, constant temperature duration, and heating and cooling rates.

Different standards provide varying provisions for the heat treatment temperature of carbon steel pipelines after welding. The specific data are presented as follows:

- ASME B31.3-2018: 595-650°C

- GB/T 20801.4-2020: 595-650°C

- GB 50235-2010: 600-650°C

- SH/T 3501-2021: 600-650°C

It can be observed that the provisions for the heat treatment temperature of steel pipelines after welding are consistent between GB/T 20801.4-2020 and ASME B31.3, as well as SH/T 3501-2021 and GB 50235.

Heating can be accomplished through resistance heating or induction heating. The temperature gradient should be minimized during heating to maintain uniform temperature. Thick-walled pipes utilize electromagnetic induction heating, which achieves a smaller temperature difference between the inner and outer walls compared to flexible ceramic resistance heating, resulting in better heat treatment effects.

ASME B31.3-2018 stipulates that for

carbon steel pipes with a wall thickness of ≤50mm, the constant temperature time is calculated as 1 hour for every 25mm of wall thickness, with a minimum of 15 minutes. For wall thicknesses >50mm, the minimum constant temperature time is 2 hours, increasing by 15 minutes for every additional 25mm of wall thickness. GB/T 20801.4-2020 stipulates the constant temperature time in accordance with ASME B31.3. GB 50235-2010 specifies that the constant temperature time is 2.4 minutes per millimeter, with a minimum of 1 hour.

When stress corrosion resistance is required in a specific medium environment, the joint of the carbon steel pipe should be heat treated after welding, regardless of the wall thickness. This treatment can reduce the residual stress in the joint, temper the microstructure of both the welding seam and the heat-affected zone, improve corrosion resistance, and lower the hardness of the weld and the heat-affected zone. Conversely, the effectiveness of the heat treatment can be evaluated by measuring the hardness of both the welding seam and the heat-affected zone.

To prevent stress corrosion cracking, SH/T 3059-2019 specifies that carbon steel pipelines should be heat treated after welding under the following special media and working conditions.

(1) Wet Hydrogen Sulfide Stress Corrosion Environment

In a wet hydrogen sulfide stress corrosion environment, the pipeline should be made from low carbon steel or carbon manganese steel with a carbon equivalent w(CE)≤0.40%. The material should be killed steel to enhance its mechanical properties. The pipeline should undergo heat treatment after welding, and the HB hardness value of the welding seam and heat-affected zone after treatment should not exceed 200.

(2) Alkali Stress Corrosion Environment

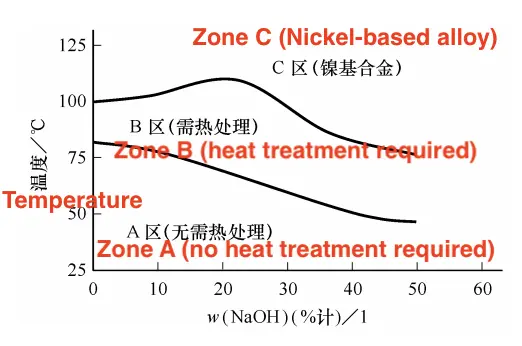

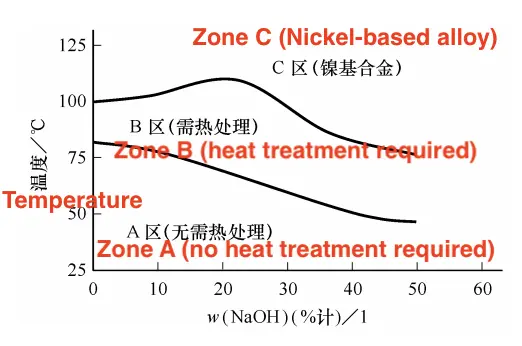

The stress corrosion cracking of carbon steel in alkaline solutions is related to temperature, alkaline concentration, and stress; the corrosion of carbon steel intensifies with increasing alkaline concentration and temperature. The allowable temperature and concentration limits for carbon steel in alkaline solutions are shown in Figure 1.

Figure 1 The allowable temperature and concentration limits for carbon steel in alkaline solutions

Figure 1 indicates that in the B zone, carbon steel should undergo stress relief heat treatment after welding to avoid alkaline stress corrosion cracking. In the A zone, carbon steel can be exempted from post-weld heat treatment, while in the C zone, the pipeline should be made from nickel-based alloy.

(3) Liquid Ammonia Corrosive Environment

When using carbon steel in a liquid ammonia corrosive environment, the water content w(H2O) in the liquid ammonia should be ensured to be greater than 0.2%, and stress relief heat treatment should be performed after welding. The hardness of the weld joint and the heat-affected zone should be tested to ensure that the hardness value does not exceed 185 HB.

NACE SP 0472-2015 states that stress corrosion damage in oil refining and petrochemical equipment primarily includes sulfide stress corrosion cracking (SSC) and alkaline stress corrosion cracking (ASCC), with SSC being a common form of hydrogen-induced stress cracking. To prevent hydrogen-induced stress cracking in carbon steel pipelines, the HBW hardness value of the welding seam metal should not exceed 200, the HV10 hardness value of the heat-affected zone should not exceed 248, and the hardness detection ratio of the weld joint should be at least 5%. To control the hardness of the welding heat-affected zone, the requirements for controlling the chemical composition of the base material are as follows: when w(C)>0.18%, the carbon equivalent w(CE)≤0.43%; when the wall thickness of the pipeline component is δ>25 mm, the carbon equivalent w(CE)≤0.45%w; when w(C)≤0.18%, the user specifies the maximum value of w(CE), with w(V)≤0.02%, w(Nb)≤0.02%, and w(V+Nb)≤0.03%. Additionally, the minimum post-weld heat treatment temperature and preheating temperature must be controlled. The recommended heat treatment temperature is 620°C, and the preheating temperature is 93°C. When corrosive media such as liquid ammonia or alkali are present in carbon steel pipelines, to prevent alkaline stress corrosion cracking, the post-weld heat treatment temperature of the welded joint should be controlled between 635°C and 650°C, with a minimum constant temperature time of 1 hour. For alkaline carbonate-acid aqueous solution media, the post-weld heat treatment temperature of the blanching joint should not be lower than 649°C.

4. Exemption Conditions for Post-Weld Heat Treatment

ASME B31.3-2018 stipulates that, during design, more stringent heat treatment requirements can be formulated based on the medium and working conditions. Additionally, the restriction on wall thickness for exempting carbon steel pipelines (P-No.1) from post-weld heat treatment has been removed. It is stipulated that carbon steel pipeline welded joints can be exempted from post-weld heat treatment when the following conditions are met: if the nominal wall thickness is greater than 25 mm, the preheating temperature must be at least 95°C; if the nominal wall thickness is greater than 5 mm, a multi-layer welding process should be used.

The heat treatment requirements in GB/T 20801.4-2020 are based on material performance, hot and cold processing, and welding properties, without considering the medium and working conditions. For example, carbon steel and carbon-manganese steel pipes with a wall thickness greater than 20 mm must undergo post-weld heat treatment, while those with a wall thickness of 20 mm or less may be exempt. GB 50235-2010 refers to ASME B31.3 for post-weld heat treatment temperature, holding time, and wall thickness of pipes and their components. Specifically, carbon steel pipes with a wall thickness of 19 mm or less can be exempted from post-weld heat treatment.

SH/T 3501-2021 stipulates that for carbon steel pipes exposed to specific corrosive media, heat treatment must be performed regardless of pipe thickness, according to design requirements. The exemptions and conditions for post-weld heat treatment of carbon steel pipes in different standards are presented in Table 3.

Table 3 Exemption conditions for post-weld heat treatment of carbon steel pipelines

| Standard |

Exemption from Heat Treatment |

Wall Thickness (mm) |

Other Conditions |

| GB 50235-2010 |

Yes |

≤19 |

None |

| GB/T 20801.4-2020 |

Yes |

≤20 |

None |

| SH/T 3501-2021 |

Yes |

≤20 |

None |

| GB/T 32270-2015 |

Yes |

≤25 |

w(C) ≤ 0.35%, carbon steel or carbon manganese steel |

| DL/T 869-2021 |

Yes |

≤30 |

A-I steel [w(C) ≤ 0.35%, carbon steel] |

| DL/T 869-2021 |

Yes |

≤20 |

A-II, A-Dish steel (ordinary low alloy steel) |

| ASME B31.3-2018 |

Yes |

≤25 |

δ>5 mm, multi-layer welding |

| ASME B31.3-2018 |

Yes |

>25 |

Multi-layer welding, ≥95°C preheating |

| ASME B31.1-2020 |

Yes |

≤25 |

δ>5 mm, multi-layer welding |

| ASME B31.1-2020 |

Yes |

>25 |

Multi-layer welding, ≥95°C preheating |

Whether carbon steel pipelines require post-weld heat treatment should be determined by the design based on the performance, structural characteristics of the steel, process media, working conditions, and other factors. If the design does not specify the requirements for post-weld heat treatment, the construction unit should determine them according to the provisions of the standards adopted for the project. The design documents stipulate that for carbon steel pipelines under stress corrosion conditions, all pipe welded joints across the full wall thickness range should undergo heat treatment according to the design requirements to improve or maximize the corrosion resistance of the material.

Although current pipeline standards in China refer to the relevant provisions of ASME B31.3 during their revision, the thickness regulations for carbon steel pipelines exempted from post-weld heat treatment remain relatively conservative. Construction under these conditions will inevitably increase costs and energy consumption, and unnecessary or excessive heat treatment may lead to material performance degradation. Therefore, it is suggested that the standard drafting unit conduct targeted welding test research to examine the performance of carbon steel pipeline welded joints in the as-welded state, exceeding the thickness exempted from post-weld heat treatment. Furthermore, when revising standards such as GB/T 20801.4-2020, GB 50235-2010, and SH/T 3501-2021, the relevant provisions on post-weld heat treatment should be modified promptly to specify the scope and conditions of exemption.