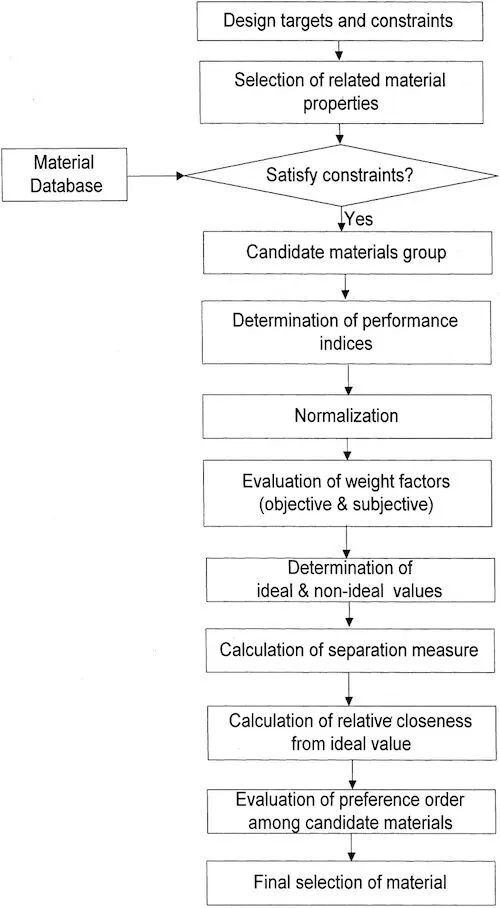

The selection of materials for gathering and transportation pipelines in oil and gas fields should focus on design pressure, temperature, service life, the nature of the corrosive medium, and the production conditions of oil, gas, and water. Early assessment of the corrosive medium conditions is essential. For design conditions with a carbon dioxide partial pressure below 0.021 MPa and a hydrogen sulfide partial pressure below 0.3 kPa, carbon steel or other cost-effective materials may be suitable. When design conditions exceed these thresholds, the suitability of the pipe should be assessed using relevant material selection standards, calculation software, or laboratory tests. An economic evaluation of suitable materials should then be conducted before finalizing the material selection strategy, as illustrated in Figure 3.

Figure 3 Selection process of oil and gas field gathering and transportation pipes

2.1 Corrosion Evaluation Methods

2.1.1 Corrosion Evaluation Standards

Due to the complexity of corrosive environments in oil and gas gathering and transportation systems, providing standardized guidelines for material selection under conditions with multiple corrosive agents is challenging. However, certain standards provide explicit guidance for individual corrosion factors.

(1) Carbon Monoxide (CO) Corrosion: According to SY/T 0076-2008 'Natural Gas Dehydration Design Specifications,' when the CO partial pressure exceeds 0.021 MPa, corrosion protection measures must be implemented. The diagram for corrosion prediction, located in the appendix, can be used, in conjunction with temperature and CO₂ partial pressure, to evaluate the corrosion rate on carbon steel. This method is typically more conservative than other prediction methods.

(2) Hydrogen Sulfide (H₂S) Corrosion: The NACE MR0175 series standards, GB/T 20972-2008 'Petroleum and Natural Gas Industry - Materials for Hydrogen Sulfide Environments in Oil and Gas Production,' and SY/T 0599-2018 'Technical Specifications for Metallic Materials for Natural Gas Surface Facilities Resisting Sulfide Stress Cracking and Stress Corrosion Cracking' provide material selection guidelines for varying hydrogen sulfide concentrations. The sulfide stress cracking (SSC) zones of the environment can be determined by the hydrogen sulfide partial pressure and in-situ pH levels. These SSC zones are classified into four regions: SSCO, SSC1, SSC2, and SSC3, with the severity of cracking increasing progressively across these regions. To inform design and construction, the standard specifies the minimum yield strength of the pipe for each region, as well as the hardness of both manufactured and on-site welds, to prevent SSC and hydrogen-induced cracking (HIC) during pipe operation.

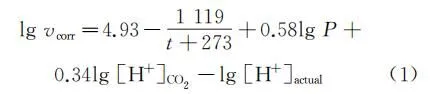

2.1.2 Corrosion Prediction Model

The corrosion prediction model is predominantly semi-empirical. The De Waard CO₂ corrosion model is a widely-used model for predicting the CO₂ corrosion rate (8-10, see formula (1)). Developed by De Waard and Nesic, this model is based on the principles of corrosion kinetics. It breaks down the CO₂ corrosion rate into two components: the activation reaction rate and the ion transfer rate, with empirical parameters derived from corrosion data.

Vcorr is the corrosion rate in mm/a; T is the temperature in °C; P is the CO₂ partial pressure in MPa.

The Electronic Corrosion Engineer (ECE) is a corrosion prediction tool developed based on De Waard's semi-empirical formula. It accounts for the effects of oil wetting and the influence of H₂S, while modifying the calculation principles for pH. Compared to the semi-empirical formula, the corrosion simulation results from the ECE software align more closely with actual corrosion data observed in production environments. When calculating the corrosion rate, input parameters include the pipe's outer diameter, wall thickness, carbon content, oil, gas, and water production rates, crude oil viscosity, the injection rate and efficiency of corrosion inhibitors, and the concentration and partial pressure of the corrosive medium. The output provides the maximum average corrosion rate and pitting rate at both the top and bottom of the pipe. Additionally, the ECE software includes a module for assessing the suitability of corrosion-resistant alloys under various operating conditions. Designers can assess the suitability of corrosion-resistant alloys by entering the partial pressure and concentration of the corrosive medium.

2.1.3 Indoor Corrosion Evaluation Test

An indoor corrosion evaluation test simulates actual field conditions to evaluate corrosion behavior. This test is typically performed in a high-temperature, high-pressure reactor. Test parameters such as temperature, flow rate, cycle duration, and the partial pressure of corrosive gases are adjusted to closely replicate operational conditions. The medium is either directly sampled on-site or simulated water samples are prepared for the test. Upon completion of the test, the corrosion characteristics of the sample surface are recorded, along with any quality changes caused by corrosion. The corrosion rate of the pipe is then determined. The water quality analysis and evaluation standards for this test typically include SY/T 5523-2016 "Oilfield Water Analysis Methods" and SY/T 0026-1999 "Water Corrosion Test Methods," among others.

2.2 Principles for Selecting Pipes Under Typical Operating Conditions

The selection of pipes for gathering and transportation systems is based on the composition and partial pressure range of the corrosive components in the medium. The operating conditions can be classified into four categories: conventional conditions, CO₂-containing conditions, H₂S-containing conditions, and H₂S/CO₂-containing conditions. The classification of these conditions is outlined in Table 3.

Table 3: Classification of Typical Working Conditions for Gathering and Transmission Pipelines

|

Working Condition Type |

Corrosion Factor (MPa) |

H₂S Partial Pressure / |

CO₂ Partial Pressure (MPa) |

|

Conventional Operating Conditions |

H₂O, Cl⁻ |

< 0.0003 |

< 0.021 |

|

CO₂-Containing Operating Conditions |

CO₂, H₂O, Cl⁻ |

< 0.0003 |

≥0.021 |

|

H₂S-Containing Operating Conditions |

H₂S, H₂O, Cl⁻ |

≥ 0.0003 |

< 0.021 |

|

H₂S/CO₂-Containing Operating Conditions |

H₂S, CO₂, H₂O, Cl⁻ |

≥ 0.0003 |

≥0.021 |

Table 4: Selection Principles of Pipes Under Typical Working Conditions

|

Working Conditions |

Temperature |

Material Category |

Pipe Type |

Standards |

|

Normal Working Conditions |

<60 °C |

Non-metallic pipes |

Steel skeleton reinforced polyethylene pipe, polyethylene, flexible composite pipe |

GB/T 15558, SY/T 6662 |

|

- |

|

Carbon steel or low alloy steel |

GB/T 6479, GB/T 9711 |

|

|

CO₂-Containing Working Conditions |

<60 °C |

Non-metallic pipes |

Steel skeleton reinforced polyethylene pipe, polyethylene, flexible composite pipe |

GB/T 15558, SY/T 6662 |

|

≥60 °C |

Carbon steel or low alloy steel |

Same as normal working conditions |

Same as normal working conditions |

|

|

H₂S-Containing Working Conditions |

- |

Carbon steel or low alloy steel |

20 (SSC 3), L245, L290, L360 (SSC 3), L415 (SSC 1/SSC 2) |

GB/T 6479, GB/T 9711 |

|

H₂S/CO₂-Containing Working Conditions |

<60 °C |

Carbon steel or low alloy steel |

Same as H₂S-containing working conditions |

Same as H₂S-containing working conditions |

|

≥60 °C |

Carbon steel or low alloy steel |

Determined by technical and economic comparison |

Same as H₂S-containing working conditions |

The selection principles for materials under the typical operating conditions outlined above can be implemented in accordance with the recommendations in Table 4. Along with the results from software calculations and corrosion evaluation tests, additional anti-corrosion measures, such as corrosion inhibitors and coatings, are required in severe corrosion environments. Beyond the guidelines provided in Table 4, specific restrictions for different pipe types, as stipulated by relevant standards, must also be taken into account. For instance, the GB 50350-2015 "Oilfield Oil and Gas Gathering and Transportation Design Code" restricts the use of pipes specified in GB/T 8163-2018 "Seamless Steel Pipes for Fluid Transportation" to diameters smaller than DN300mm and pressures below 4MPa. This is primarily because the GB/T 8163-2018 standard has lower acceptance criteria for pipes, fewer factory inspection requirements, and no heat treatment specifications, making it challenging to ensure the quality of pipes in gas transmission applications. Furthermore, different standards impose varying restrictions. Therefore, when selecting pipes according to Table 4, it is essential to consult relevant national and industry standards, such as GB 50349-2015 "Gas Field Gathering and Transportation Design Specifications," GB 50350-2015, and GB 50391-2014 "Oil Field Water Injection Engineering Design Specifications."

3. Conclusion

Carbon steel and low-alloy steel pipes remain the primary choice for most surface construction projects in the oil and gas industry. However, non-metallic pipes have gained widespread adoption in recent years due to their advantages, such as excellent corrosion resistance, extended service life, and ease of installation. This trend indicates a gradual shift towards replacing steel pipes. Despite these advantages, temperature resistance remains a critical challenge for non-metallic pipes, particularly in high-temperature gas pipelines, where their pressure resistance significantly decreases. Additionally, there is an urgent need to standardize the design, construction, and acceptance criteria for non-metallic pipes to ensure project quality. As pipe materials diversify and standardize, a broader range of options will become available for selecting surface gathering and transportation pipes in oil and gas fields. By choosing pipes with superior technical and economic performance, the investment costs for surface engineering construction can be significantly reduced, while extending the operational service life of pipelines.