Through the close cooperation and analysis of welding technicians, flaw detection personnel in the workshop and quality department, it was finally determined that the root cause of tungsten inclusion in the welding seam was excessive welding current, and the tungsten electrode of 2.4 mm used on site could not withstand the heavy current of more than 160A. Continuous long-term welding leads to overheating and melting of the end of the tungsten rod; at the same time, the tungsten pole ground on site is not standardized, and the diameter and shape of the tungsten pole tip do not meet the technical requirements. The technical department issued an order of rectification to the workshop according to the company's management due to the violation of the process requirements on site.

The rectification measures taken by the workshop are mainly as follows:

(1) Conduct argon arc welding to avoid tungsten inclusion and offer quality improvement special training, so that welders understand the technical requirements of tungsten rod grinding, diameter selection and applicable current in argon arc welding.

(2) Purchase special equipment for automatic grinding of tungsten poles to replace irregular manual operations. However, when rectifying, we are faced with a wide range of processing and production tasks of pipes.

Workers can only work overtime for construction; the implementation effect of the mandatory current limit is not ideal, and the quality of welding seam is sometimes good and sometimes bad. In the X-ray inspection in September, there were still 24 films with tungsten inclusions, and the qualified rate of filming was lower than the monthly target value.

3. Improvement in the argon arc welding process

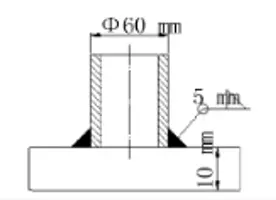

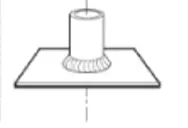

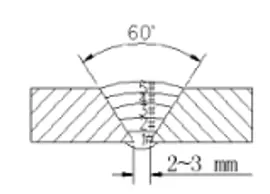

To completely solve the problem of tungsten inclusion in tube processing and welding, technicians decided to improve the process after repeated research, changing the diameter of the tungsten pole from 2.4mm to 3.2mm. Select pipe diameters of different specifications and sizes for large-scale product welding process approval test. The base metal grade is Grade 410. The welding method is argon arc welding plus CO2 gas shielded welding. The joint forms include pipe butt welding seams and pipe flange fillet welding seams. See Table 3 for butt welding evaluation tests of pipes and Table 4 for welding process parameters.

Table 3 Butt welding evaluation tests of pipes

| Items | Sizes of Base metal/mm | Welding positions | Groove forms and weld bead arrangement | |

| Diameters of pipes | Wall thickness | |||

| 1 | Ф114 | 7 | Horizontal roll welding of pipes |

|

| 2 | Ф273 | 13 |  |

|

| 3 | Ф60 | 5 | Horizontal fillet welding of pipe flanges |

|

Please note that 1 to 5 are the serial numbers of the welding bead.

Table 4 Welding process parameters

| Items | Welding bead items | Welding methods | Welding material diameters/mm | Welding current/A | Welding voltage/V | Welding speeds/ ( mms-1) |

| 1 | 1# to 3# | Argon arc welding | 2.4 | 170 | 14 | 1.70 to 2.10 |

| 4# | CO2 gas shielded welding | 1.2 | 155 to 160 | 24 | 2.65 | |

| 2 | 1# to 2# | Argon arc welding | 2.4 | 168 | 14 | 1.50 |

| 3# to 5# | CO2 gas shielded welding | 1.2 | 155 to 160 | 22 | 1.90 to 2.40 | |

| 3 | 1# | Argon arc welding | 2.4 | 160 | 14 | 1.40 |

The 3 test plates were subjected to the welding procedure approval test in accordance with the requirements specified in the China Classification Society (CCS) "Requirements for Materials and Welding". The test results were all qualified, and the CCS surveyor signed and approved; the process improvement was finally completed.

4. Conclusion

The implementation plan of the shipyard changed the diameter of the tungsten electrode from 2.4mm to 3.2mm, and adopted a welding process with large parameters (heavy current), which completely solved the frequent tungsten inclusions in the bottoming welding seam of carbon steel pipes in the workshop. While ensuring the quality and progress of product construction, the process optimization scheme increased the welding efficiency by about 30%, effectively ensuring the quality of subsequent ship welding seams. This process improvement has improved the on-site service awareness of technicians and strengthened the collaboration and communication between the technical department and the construction workshop. Welding technicians realize that it is necessary to fully consider and adapt to the actual situation on site when formulating the product process; in the process of welding procedure approval test, it is not only necessary to carry out tests under conventional conditions, but also to study welding rules under special and complex operating conditions. Carry out product welding tests in a targeted manner, and continuously optimize and improve the welding process.