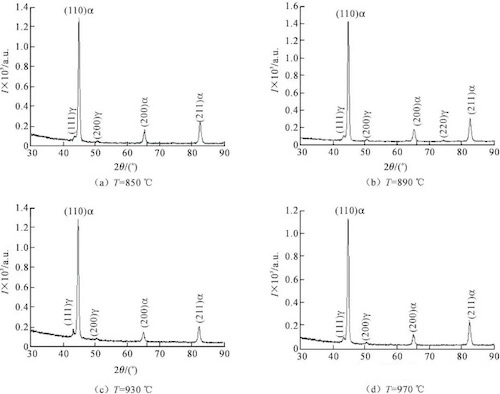

Figure 2 is the Xrd diffraction pattern of the bainite steel pipe heated and normalized at different temperatures (850°C, 890°C, 930°C and 970°C), and tempered at 300°C. It can be seen from Figure 2 that when heating at different temperatures for normalizing and tempering at 300°C, the Xrd diffraction peaks of bainite steel pipes mainly include ferrite peaks (α) and austenite peaks (γ), and no carbide peaks exist, indicating that there is no carbide phase in the structure. Therefore, under the conditions of heating at different normalizing temperatures and tempering at 300°C, the structure of the bainite steel pipe should be bainitic ferrite and austenite, and it should be a carbide-free bainite structure.

Figure 2 Xrd diffraction patterns of impact samples at different normalizing temperatures

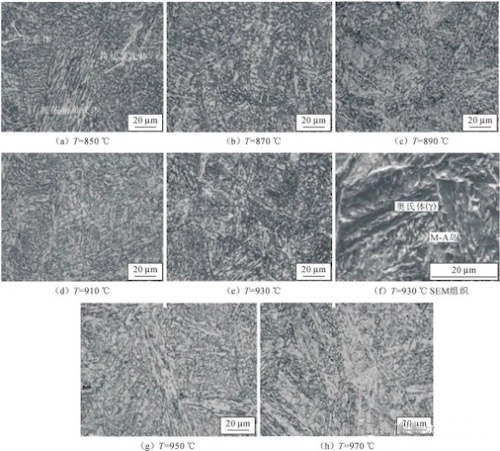

Figure 3 is the microstructure morphology of the bainite steel pipe heated and normalized at different temperatures and tempered at 300°C. Combined with the Xrd diffraction analysis in Figure 2, when the experimental material is heated at 850 to 970°C and tempered at 300°C, the microstructure is all bainitic ferrite and retained austenite, that is, carbide-free bainite structure. The carbides in the typical bainite structure are replaced by austenite, and austenite is a tough phase due to the existence of no carbide phase in the structure, which can improve the plasticity, toughness, wear resistance and contact fatigue life of bainite steel. Therefore, the carbide-free bainite structure has good toughness.

Figure 3 Microstructure of impacted specimens heated at different normalizing temperatures and tempered at 300°C

It can be seen from Figure 3(a) that the microstructure is mainly composed of granular bainite, lath carbide-free bainite and a small amount of massive ferrite when heated at 850°C. Granular bainite is composed of martensite (m)-austenite (a) islands arranged roughly in a direction on the bainitic ferrite matrix. The formation of m-a islands is due to the carbon atoms in the cooling process. Diffusion from the ferrite/austenite interface to the austenite increases the carbon content of the retained austenite and stabilizes it, and then part of the carbon-rich austenite undergoes martensitic transformation in the cooling process, which forms m-a islands with stable austenite. The lath-shaped bainite structure formed by heating and air cooling at 850°C has longer laths and a relatively coarse structure. As the heating temperature increases, the normalized structure is refined. It can be seen from Figure 3(B) that the microstructure under air cooling at 870°C is mainly composed of granular bainite structure and a small amount of massive ferrite, and compared with the normalizing structure heated at 850°C, there are fewer long laths in the structure; the organization has been refined. Figure 3(c) and Figure 3(d) are the microstructures heated and air-cooled at 890°C and 910°C, which are consistent with the morphology of the normalized structure heated at 870°C, and are also granular bainite and a small amount of massive ferrite.

It can be seen from Figure 3(E) that the microstructure heated at 930°C for normalizing is mainly granular bainite and lath-shaped carbide-free bainite. Compared with the structures at the previous heating temperatures, the microstructure heated at 930°C is more refined, which is specifically manifested in the transformation structure of different phases in a prior austenite grain, and the fine structure can improve the impact energy of the experimental material. It can be seen from Figure 3(f) that when heated and normalized at 930°C, the residual austenite in the carbide-free bainitic ferrite is distributed between the laths of the lath bainite. The islands surrounded by austenite distributed above are m-a islands.

It can be seen from Figure 3(g) that the microstructure after normalizing at 950°C is mainly composed of lath bainite, granular bainite and a small amount of ferrite. As the length of the slab increases, the grains coarsen, and the increase in the grain size will reduce the toughness of the experimental material. It can be seen from Figure 3(H) that the microstructure of heating and normalizing at 970°C is mainly granular bainite, lath bainite and a small amount of massive ferrite, but compared with the microstructure of the previous heating temperatures, the length of the lath increases obviously; the grains are coarsened, but the size of the lath bundles is not coarsened. The experimental material has a higher impact energy due to the thinner lath bundles and the beneficial effect of retained austenite on toughness.

3. Conclusion

1) With the increase in the normalizing heating temperature, the tensile strength of the carbide-free bainite steel pipe tends to decrease, and the overall decrease is small. When the normalizing temperature is 930°C, the tensile strength of the material is high, and the impact energy reaches the highest value, and elongation and reduction of area are high. The optimum normalizing heating temperature for the experimental material is 930℃. When normalizing at 930℃ and tempering at 300℃, the mechanical properties of the carbide-free bainite steel pipe are that rm is 971Mpa, a 18.3%, z 69% and Akv 82.6J.

2) The carbide-free bainite steel pipe is heated and normalized at different temperatures, and its microstructure is mainly carbide-free bainite and a small amount of massive ferrite. When heated at 930°C, its microstructure is relatively high, exceeding heating at 930°C; with the increase in heating temperature, the proportion of lath bainite structure in the structure of carbide-free bainite steel pipe increases; the length of lath increases, and the structure becomes coarser.