With the rapid development of China's industry, the requirements for quality of steel products are becoming more and more stringent. Among them, general structural pipes, such as general buildings, civil engineering, iron towers and other steel pipes are basic materials in the construction industry. The quality of welded steel pipes is mainly evaluated through testing methods such as flattening tests, mechanical tensile tests and high-temperature fatigue tests. Among them, the flattening test is to test the ultimate plastic deformation ability of the pipe when it is flattened and deformed without cracks under given conditions. Its advantage is that the test results can be obtained quickly.

The flattening test is one of the methods to check the quality of steel pipes. By analyzing the causes of cracking in the flattening test and taking corresponding measures, cracking in the flattening test of welded steel pipes can be solved. The experiment uses scanning electron microscope (SEM), energy dispersive spectrometer (EDS) and metallographic microscope (OM) and other equipment to analyze the causes of cracking in the flattening test of welded steel pipes in two aspects: metallographic analysis and fracture analysis.

1. Experimental materials and methods

This tested product is a steel pipe made in China. The steel used is hot-rolled Q235B ordinary carbon structural steel. It has an outer diameter of 26.8mm and wall thickness of 2.75mm. Q235B uses an 80t oxygen top-blown converter (BOF) for smelting. The plant does not use a ladle refining furnace (LF) for refining. The cross-sectional size of the continuous casting billet is 180mm × 1500mm. Its chemical composition is shown in Table 1, and the steel plate production process and performance parameters are shown in Table 2. The production processes of welded steel pipes are: steelmaking → continuous casting → hot rolling → pickling → slitting → curling → pressure measuring devices → welding → internal and external deburring → cooling → neck setting → cutting. The chemical composition of the steel pipe complies with the standard requirements of GB/T699-2008 "High-quality Carbon Steel".

Table 1 Chemical composition of the sample

| Items | C | Si | Mn | P | S |

| Content | 0.21 | 0.23 | 0.53 | 0.013 | 0.012 |

| GB/T 699-2008 | 0.17 to 0.24 | 0.17 to 0.37 | 0.35 to 0.65 | Less than and equal to 0.04 | Less than and equal to 0.04 |

Tensile specimens were taken from this steel pipe. The sample type was a pipe section specimen. The test was carried out according to the GB/T228.1-2010 "Tensile Tests of Metals Part 1: Test Methods at Room Temperatures" standard. The results met the requirements of the standard, as shown in Table 3.

| Tapping temperature/℃ | Fine rolling temperature/℃ | Final rolling temperature/℃ | Curling temperature/℃ | Yield strength/MPa | Tensile strength/MPa | Elongation/% |

| About 1230 | About 1000 | About 900 | About 650 | 263.5 | 456.3 | 31.2 |

Table 3 Mechanical properties of the sample

| Yield strength/MPa | Tensile strength/MPa | Elongation/% |

| 285 | 430 | 26 |

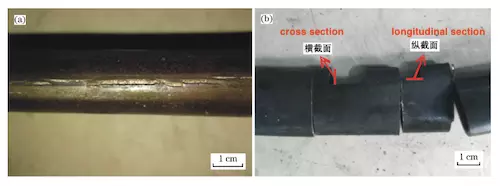

Cut and sample the cracked part of the steel pipe, and cut the cross-section and longitudinal section, as shown in Figure 1. Use tools to open the cracks to prepare fractured specimens. The prepared samples were ground, polished, ultrasonic cleaned, dried, and comprehensively analyzed using scanning electron microscopes, energy spectrometers, metallographic microscopes, and other instruments. The samples were corroded with 4% nitric acid alcohol and then analyzed using a metallographic microscope. Observe its organization.

(a) Macroscopic morphology of the sample (b) Sampling positions

Figure 1 Macroscopic morphology and sampling positions of the sample