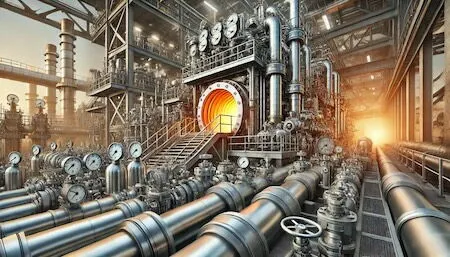

As a unique type of process equipment, delayed coking units effectively separate petroleum coke from crude oil and convert it into usable products. Due to their important role in the oil refining process, delayed coking units are widely used in the petrochemical industry. These units not only significantly improve the utilization of oil resources but also offer energy-saving and environmentally friendly advantages, meeting modern industry’s demand for green production. As a result, these units have gained increasing attention and are being applied more widely around the world.

As one of the key pieces of equipment, the heating furnace in a delayed coking unit operates at temperatures reaching hundreds of degrees Celsius and endures a harsh working environment. Under these conditions, the chromium-molybdenum alloy steel pipelines used in the heating furnace face multiple challenges, including high temperature, high pressure, and corrosion. Therefore, the quality of welding is directly related to the safety, reliability, and service life of the unit.

This paper introduces the welding process of

chromium-molybdenum alloy steel pipes used in the heating furnace of delayed coking units and discusses key aspects, including the selection of suitable welding materials, optimization of welding parameters, control of welding deformation, and prevention of welding defects. The goal is to provide a theoretical basis and practical guidance for enhancing the unit’s safety and extending its service life.

Chromium-molybdenum alloy steel is a metal with excellent corrosion and high-temperature oxidation resistance, making it widely used in the chemical, petroleum, and petrochemical industries. Despite its advantages, chromium-molybdenum alloy steel has poor weldability and is prone to cracking and other defects, making the selection of an appropriate welding method crucial. Commonly used welding methods include argon arc welding, electric arc welding, and argon-electric welding. Argon arc welding is a widely used technique, known for its stable welding arc, dense welding seams, and attractive finish. However, due to its low efficiency and high cost, it is typically reserved for welding thin parts. Electric arc welding, a traditional method, provides fast welding speed and strong welding seams, but it also has drawbacks, such as susceptibility to thermal stress and high welding skill requirements for welders. Argon-electric welding combines the benefits of both methods: argon arc welding is used for root welding to ensure high-quality root joints, while electric arc welding is used for filling and capping, greatly enhancing welding efficiency.

Due to the high-temperature environment in delayed coking, it is essential to select welding materials that can withstand extreme heat. Additionally, considering that the welded metal structure must maintain good toughness and corrosion resistance, choosing an appropriate welding process is crucial. After extensive discussions and experimental verification, argon arc welding was selected as the preferred method. In practice, various welding parameters are adjusted to optimize the welding outcome. Factors such as welding current, welding speed, and others must be carefully controlled to achieve the best results. Furthermore, it is important to source welding rods and wires from qualified suppliers. These materials must have quality certification and be kept in proper condition—free from damage or moisture, as outlined in Table 1. The outer coating of the welding rod must be intact, with no peeling or cracks. It is also vital to ensure that the welding rods are dried at the correct temperature to prevent issues like thermal deformation in high-temperature environments. For details, refer to Table 2. Finally, during the welding process, it is crucial to maintain a clean and hygienic work area to avoid contamination that could negatively affect the welding quality.

Table 1 Material Selection Table

| Steel |

Welding Rod Grade |

Welding Wire Specifications (mm) |

Welding Wire Grade |

Welding Wire Specifications (mm) |

| 1Cr5Mo |

CHH507R |

3.2 |

H1Cr5Mo |

2.5 |

| 1Cr9Mo |

CHH707R |

3.2 |

ER80S-B8 |

2.5 |

Table 2 Welding Rod Drying Temperature

| Welding Rod Brand |

Drying Temperature (°C) |

Constant Temperature Time (h) |

Insulation Temperature (°C) |

| CHH507R / CHH707R |

350 |

1 |

100 - 150 |

Note: If the welding material manufacturer provides specific drying instructions, follow the guidelines on the packaging. If no instructions are provided, use the conditions specified in this table.

The welding process flow for the heating furnace in a delayed coking unit mainly consists of four stages: preheating, welding preparation, welding, and cooling. In the preheating stage, the welding seam areas on the unit’s pipeline must be preheated to facilitate the subsequent welding process. Additionally, the surface of the base material should be treated, such as by grinding or sandblasting to remove any rust, ensuring the material's quality.

During the welding preparation stage, the welding areas on the delayed coking unit need to be cleaned and trimmed to ensure precise welding positioning. Factors such as welding position and quantity should also be considered to create an appropriate welding plan. In the welding stage, argon arc welding or other suitable welding methods are used. Care should be taken to maintain uniform wire distribution within the molten pool to prevent welding defects caused by inconsistent wire feeding.

In the cooling stage, the welded area should be slowly cooled to room temperature after a dehydrogenation treatment to prevent cracks and other defects. The entire welding process must undergo multiple tests to identify the optimal parameter combination.