1. Introduction

High-pressure boilers are often at high temperatures and high pressure. The risk of oxidation and corrosion of seamless steel pipes under the long-term action of high-temperature steam is relatively great. Therefore, there are strict requirements for their materials, heat treatment, and processing technology. Besides having high strength, good oxidation resistance and corrosion resistance, high-pressure boilers should have good organizational stability. There is a fracture accident for a high-pressure boiler after it is used for 6 years, causing great economic losses. The failure of a high-pressure boiler is mainly caused by the cracking of the seamless steel pipe. The seamless steel pipe is made from 20 MnG. Feasible prevention and improvement suggestions for the causes of cracking of steel pipes are put forward in this article.

2. Experimental processes and results

2.1 Chemical composition

An analysis sample of chemical composition was taken from the fracture of the seamless steel pipe for testing. The results are shown in Table 1. It can be seen from Table 1 that the test results of the chemical composition of the 10 elements of the seamless steel pipe meet the requirements of the 20MnG in the standard GB/T5310-2017 Seamless Steel Pipes for High Pressure Boilers, and the chemical composition is qualified.

Table 1 Test results of the chemical composition of seamless steel pipes (unit for mass fraction: %)

| Items | C | Si | Mn | P | S | Cu | Cr | Ni | Mo | V |

| Measured values | 0.20 | 0.22 | 0.52 | 0.012 | 0.006 | 0.02 | 0.03 | 0.02 | 0.01 | 0.01 |

| Standard values (20MnG) | Between 0.17 and 0.23 | Between 0.17 and 0.37 | Between 035 and 0.65 | Less than or equal to 0.025 | Less than or equal to 0.015 | Less than or equal to 020 | Less than or equal to 0.25 | Less than or equal to 0.25 | Less than or equal to 0.15 | Less than or equal to 0.08 |

2.2 Analyses for Hardness

Three samples for hardness were taken from the fracture of seamless steel pipes for testing, which were identified as 1#, 2#, and 3#. It can be seen from Table 2 that their Vickers hardness also meets the requirements.

Table 2 Vickers hardness test results of seamless steel pipes

| Samples for Hardness | Technical requirements (20 MnG) | Test results HV10 |

| 1# | Between 125 and 170 | 128.5, 130.6, 132.4 |

| 2# | 132.2, 134.6, 135.5 | |

| 3# | 134.6, 131.1, 130.6 |

2.3 Analyses for tensile performance

Three samples for tensile tests were taken along the axial direction of the seamless steel pipe, and the WDW-100 micro-controlled electronic universal testing machine was used for the tensile test at normal temperature. The test results are shown in Table 3. It can be seen from Table 3 that there is no abnormality in the various indicators, and the yield strength, tensile strength and elongation after fracture all meet the technical requirements of the standard GB/T 5310-2017 Seamless Steel Pipes for High Pressure Boilers.

Table 3 Test results of tensile properties of seamless steel pipes

| Samples for tensile tests | Yield strength /MPa | Tensile strength /MPa | Elongation after fracture /(%) |

| 1# | 288 | 482 | 30.0 |

| 2# | 292 | 485 | 30.0 |

| 3# | 286 | 478 | 30.5 |

| Technical requirements (20 MnG) | Higher than or equal to 240 | From 415 to 560 | Higher than or equal to 22 |

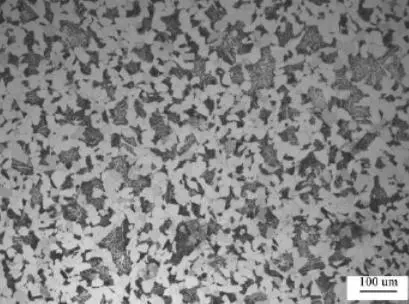

2.4 Metallographic analyses

Take the sample along the axial section at the fracture of the seamless steel pipe for metallographic tests. After grinding, polishing and corrosion, observe it under the Leica DMIRM metallographic optical microscope. The metallographic structure is shown in Figure 1. The metallographic structure is ferrite (the white area) and pearlite (the dark area). The pearlite lamellar cementite is intermittent due to the long-term high temperature, showing slight balling in the initial stage, and the overall organization is in a good state, which meets the technical requirements of GB/T 5310-2017 Seamless Steel Pipes for high-pressure Boilers. The heat treatment of seamless steel pipes for 20MnG high-pressure boilers should be normalizing, and the microstructure should be ferrite and pearlite.

Figure 1 Metallographic microstructure of fractures of seamless steel pipes

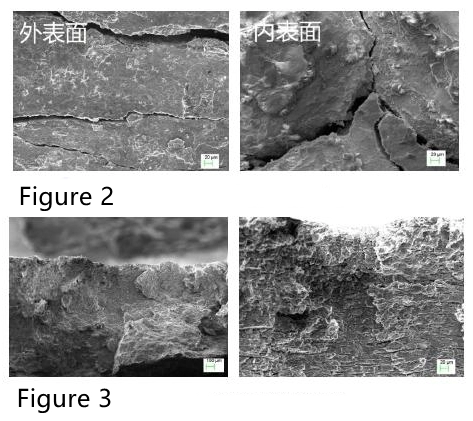

2.5 The analysis of the SEM scanning electron microscope

The Zeiss scanning electron microscope was used to observe and analyze the micromorphology of the outer surface, inner surface and cross section of the seamless steel pipe near the fracture. As shown in Figure 2, there are obvious cracks on the outer surface and inner surface of the seamless steel pipe, and the inner and outer surfaces are covered with a layer of loose rust. The energy spectrum analysis was performed for the rust scale and showed that the main components of the rust scale are oxygen, iron, silicon, chlorine, and sulfur. The chlorine content of the rust scale on the inner surface reached 7.65% and the sulfur content reached 6.32%. The microscopic morphology of the fracture surface of the seamless steel pipe is shown in Figure 3. The fracture surface of the seamless steel pipe shows tearing traces and a number of corrosion pits. The corrosion pits of the fracture surface were also analyzed by the EDS energy spectrum analyzer, and the chlorine and sulfur content are high.

3. Analysis and discussion

From the above detection results and scanning electron microscope observation and analysis, it can be seen that the chemical composition, mechanical properties and metallographic structure of the seamless steel pipe meet the requirements of the standard, so the problems of the wrong material and the heat treatment process are eliminated. From the results of SEM scanning electron microscopy and EDS energy spectrum analysis of the inner and outer surfaces and fractures of seamless steel pipes, because the high-pressure boiler has been operating under internal and external environmental conditions like high temperature vapor for a long time, oxides, chlorides and sulfide and other rust scales form on the inner and outer walls of the seamless steel pipe. As the thickness of the rust scale increases, the thermal conductivity of the seamless steel pipe reduces, and the thermal efficiency is greatly reduced. At the same time, the temperature of the steel pipe is increased, which further accelerates the corrosion of the inner and outer surfaces, resulting in unsafe factors such as reduction of thickness and effective sectional areas as well as increased internal stress of the steel pipe. Make the corroded matrix with defects crack. With the aging of seamless steel pipes and the decrease in matrix strength, the cracks gradually expanded in the radial direction to the inner and outer surfaces, and finally stress corrosion cracking occurred.

4. Conclusion

The main reason for the cracking of the seamless steel pipe for 20MnG high-pressure boiler is that the steel pipe has been in service under high temperature and high pressure for a long time, and it has gradually begun to age. The strength of the matrix has been continuously reduced. The defects on the corrosive matrix of the inner surface first crack, coupled with corrosion year in year out. At the same time, under the action of high internal stress, the cracks continue to expand and finally stress corrosion cracking occurs. It is recommended that the residual rust scale on the inner and outer walls of seamless steel pipes should be removed by chemical cleaning. Perform ultrasonic non-destructive inspection on seamless steel pipes regularly. If there is a reduction in wall thickness or corrosion crack, the seamless steel pipe should be replaced in time.