In coal chemical plants, pipelines, pipe fittings, valves, instruments and equipment are connected by flanges. The flange connection method has the advantages of reliability, convenient disassembly and not requiring flame operation. The coal chemical production process often involves high temperature, high pressure and other processes. The medium flowing in the equipment and pipeline has characteristics of high temperature, high pressure, being toxic, flammable and explosive as well as easy corrosion, which requires the flange connection to have good sealing. However, various factors such as harsh external conditions, high temperature and high pressure of the internal medium, improper installation and disassembly often cause flange leakages. Leakages of flanges can affect normal production, or cause great economic losses in a serious situation, even casualties and environmental pollution. Therefore, it is of great practical significance to study the factors that affect flange sealing.

1. Sealing principles

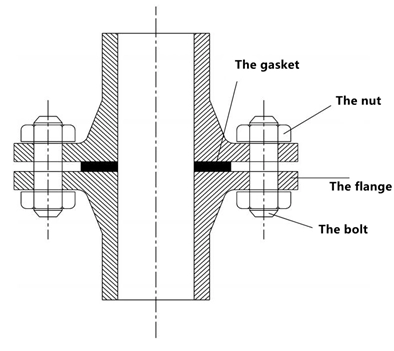

Flanges, bolts and gaskets connect the pipelines and realize the sealing of the pipelines, and the gaskets are the main sealing elements of the flange connection end. Under the action of pre-tightening force of the bolt, sufficient pressure is generated between the gasket and sealing surface of the flange, and the uneven micro geometric gap of the flange surface is filled by the gasket to achieve the purpose of sealing. The schematic diagram of the flange sealing structure is shown in Figure 1.

Figure 1 The schematic diagram of flange seal structure

There are two main forms of gasket leakages, namely interface leakages and penetration leakages. The leakage that occurs between the contact surface of the flange and gasket is the interface leakage, which is related to the size of the interface gap. The leakage caused by the fluid leaking through the gasket capillary is called the permeation leakage, which is related to structure materials of gaskets, medium temperature and pressure.

2. Analysis of seal failure factors

The factors affecting flange sealing are as the following: (1) The characteristics of flanges, bolts and gaskets, that is, conditions of the flange connection components (2) Media, pressure, temperature, external environment, etc., that is, operating conditions (3) Human factors such as installation, disassembly and operation

2.1 Flange connection components

The influence of the flange on the sealing performance is reflected in the surface roughness of the flange. Under the same working conditions, the flange surface roughness is different and the leakage rate is also different. The smaller the flange surface roughness is, the smaller the leakage rate becomes. The surface roughness of the flange should match that of the gasket. The sealing surface roughness of the non-metal gasket can be lower, and the sealing surface accuracy of the metal gasket is relatively high. In addition, the flange grade will also have an impact on the seal. When the flange deforms greatly under the action of force and moment, a leakage is likely to occur. The flange grade should be improved, and it should meet certain requirements for strength and stiffness. A flange with great rigidity has small deformation and a uniform bolt pre-tightening force can improve the sealing performance. Increasing the outer diameter and thickness of the flange and reducing the diameter of the bolt center circle can all improve rigidity of the flange.

The influence of bolts on sealing performance is mainly reflected in the pre-tightening force. If the pre-tightening force is too small and the sealing is not tight, a leakage will easily occur. If the pre-tightening force is too great, cracks will be prone to appear at the root of the flange or the gasket will be deformed, which will also cause leakage. Therefore, the pre-tightening force should be moderate, and attention should be paid to the sequence of pre-tightening. There are many factors affecting the pre-tightening force, such as elastic and plastic deformation of the flange, cleanliness of the thread, plastic deformation of the gasket, changes in temperature and pressure, quality of bolts and nuts and degrees of lubrication.

Proper deformation and resilience of gaskets are necessary conditions for sealing. The deformation of the gasket is divided into plastic deformation and elastic deformation. If the gasket material has good flexibility, the gasket can fit well with the sealing surface and the sealing effect will be very good. The resilience of the gasket can timely compensate for the separation of the sealing surface, while maintaining sufficient compression stress to maintain the seal. The greater the resilience of the gasket is, the greater the residual compression stress becomes and the better the sealing performance of the gasket will be.